Key Precautions When Using Ultrasound Equipment in Swine Production

In modern swine farming, ultrasound machines have become indispensable tools for improving reproductive efficiency and reducing production costs. These devices help farmers accurately determine sow pregnancy status, allowing them to manage breeding and farrowing schedules more effectively. However, if not used properly, these machines may fail to deliver accurate results, or worse, suffer equipment damage. In this article, we explore key precautions, common mistakes, and expert practices for maximizing the utility of ultrasound technology in pig production, with insights drawn from global veterinary standards and farmer experiences.

Importance of Ultrasound in Pig Farming

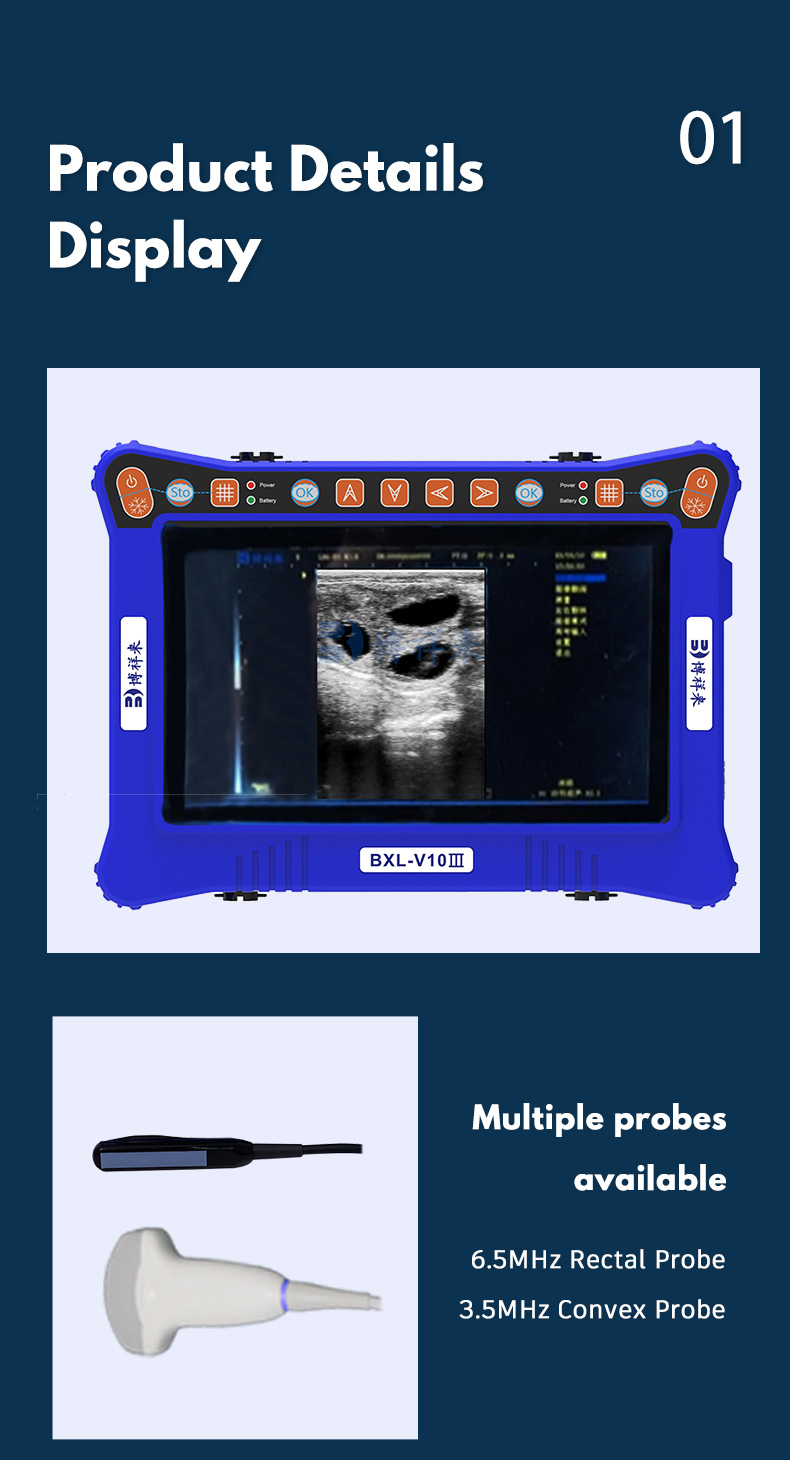

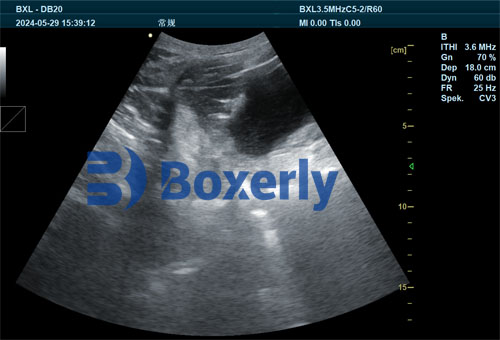

Ultrasound—particularly real-time B-mode imaging—has revolutionized reproductive management in swine. When operated correctly, it allows farm managers to detect pregnancy as early as 21 days post-breeding. This helps avoid wasted time and feed on non-pregnant sows, while also facilitating batch farrowing management.

From large-scale operations in the U.S. Midwest to technologically advanced breeding units in Europe, ultrasound is now a standard tool in modern pig farming. Yet even with its advantages, many first-time users underestimate the complexity of proper ultrasound operation.

Common Mistakes and Operational Errors

-

Skipping Device Warm-Up

When using mechanical-probe ultrasound machines—particularly in cold environments—failing to allow the device to preheat for 2–3 minutes may result in blurry or incomplete images. Electronic probes, however, generally do not require warming. -

Improper Coupling Agent Use

One of the most frequent mistakes is substituting the ultrasound gel with water, edible oil, or other liquids. These can damage the probe or reduce image clarity by hindering acoustic wave transmission. Always use veterinary-grade coupling gel to ensure optimal results and protect the equipment. -

Incorrect Probe Angle

If the transducer does not sit flush at a 90-degree angle to the sow’s abdomen, the reflection of the ultrasound waves will be scattered, leading to poor resolution or missed structures like embryonic sacs. -

Unrestrained Animals

Movement can distort images and make it difficult to interpret the scan. Without proper restraint or environmental control, such as calm lighting and quiet surroundings, scans are prone to error. -

Lack of Image Interpretation Skills

Distinguishing between early pregnancy signs like black fluid circles and advanced features like placental rings requires experience. Operators must also be able to differentiate between normal uterine fluid and post-partum residue or infections.

Best Practices and Usage Guidelines

To fully harness the benefits of ultrasound technology, the following practices are widely recommended by international veterinary standards:

-

Pre-Check Equipment

Ensure the device has sufficient battery life before use. A shutdown mid-scan not only wastes time but can stress the animal. -

Apply Proper Coupling Gel

Coat the probe generously before scanning. This enhances sound wave transmission and reduces noise in the resulting image. -

Gentle and Calm Operation

Use slow, firm contact with the animal’s body to avoid sudden movements or stress responses, which can affect scanning accuracy. -

Post-Use Disinfection

Clean the probe thoroughly with alcohol wipes after each session to prevent cross-contamination and preserve hygiene. -

Routine Calibration and Maintenance

It’s advisable to calibrate the ultrasound unit at least quarterly. Functional tests and software updates should be part of regular maintenance, especially on farms with frequent usage.

Advanced Tips to Improve Imaging Success

Beyond the fundamentals, many international producers adopt additional measures to ensure high-quality scans:

-

Optimal Timing

Perform scans early in the morning or before feeding, when sows are calmer. The period from 21 to 35 days after mating is the optimal detection window. -

Controlled Environment

Choose well-lit, quiet, and ventilated areas to minimize animal agitation. Stress can alter internal physiology and affect image clarity. -

Image Archiving

Keep digital records of scans. These images can be used for trend analysis, reproductive planning, or consulting with specialists when abnormalities appear. -

Stage-Specific Training

Learn to identify gestational landmarks at various stages. For instance:-

Day 21–28: Dark fluid pockets surrounded by echogenic walls.

-

Day 30–35: Embryo shapes and placental structures become clearer.

-

Frequently Asked Questions (FAQ)

Q1: Can beginners operate pig ultrasound machines easily?

A1: Most modern systems are designed with user-friendly interfaces and multilingual support (including English and Spanish). Instructional videos and remote coaching services are often available. With just a few sessions of hands-on practice, new users can scan sows with confidence.

Q2: What should I do if the machine malfunctions?

A2: Reputable manufacturers offer global warranty services—often with three-year coverage for the main unit and one year for accessories. Remote diagnostics and international shipping support ensure that your production is not delayed due to equipment failure.

Q3: Is ultrasound suitable for large-scale pig farms?

A3: Absolutely. Ultrasound machines are widely adopted in over 500 mid- to large-scale swine operations globally. Their proven durability and high throughput capacity make them essential in commercial breeding programs.

International Perspectives: How Foreign Producers Handle Ultrasound Use

In Denmark, where herd health protocols are among the strictest, ultrasound machines are integrated with digital breeding records. Technicians undergo certification programs to ensure accurate interpretation and traceability.

In the United States, large integrated operations use ultrasound not only for pregnancy detection but also for evaluating post-weaning uterine health, allowing for rapid culling or treatment decisions.

In China, the rise of AI-assisted ultrasound devices is enabling better detection by automatically identifying embryonic structures—a trend also emerging in European markets.

These global insights show that the key to success isn’t just having a good machine, but knowing how to use it well.

Final Thoughts: Professional Equipment Requires Professional Handling

Choosing a specialized pig ultrasound machine is just the first step. Proper operation, regular maintenance, and consistent training form the core of effective reproductive management in swine. Whether you’re running a 50-sow herd or managing thousands, understanding the nuances of ultrasound imaging ensures you extract maximum value from your investment.

With technical support, warranties, and continuous education, professional-grade machines offer peace of mind and real returns. As ultrasound technology continues to evolve—combining wireless connectivity, image enhancement, and AI-driven diagnostics—it’s never been a better time to adopt or upgrade your scanning practices.

Reference Sources:

-

Whitaker, D. A., & Smith, E. (2021). Veterinary Ultrasonography in Food-Producing Animals. Journal of Veterinary Imaging.

-

Pig Progress. (2023). “Ultrasound Use in Swine Reproduction: Practical Guidelines.” https://www.pigprogress.net/reproduction/ultrasound-use-in-swine-reproduction-practical-guidelines

-

USDA APHIS. (2022). “Best Practices for Swine Reproductive Efficiency.” https://www.aphis.usda.gov/aphis/ourfocus/animalhealth