Ribeye area & backfat depth: checking muscle and fat growth in Angus steers

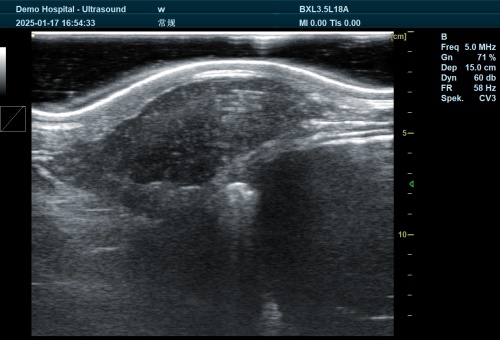

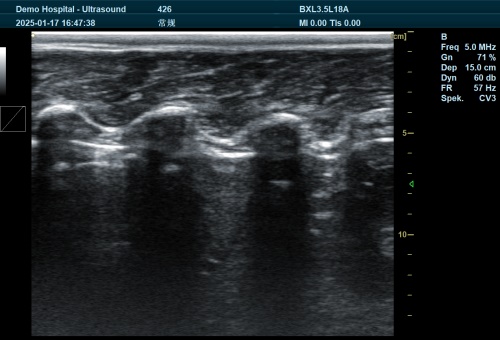

Hey there! I’ve been working with beef cattle for years, and when I talk with foreign colleagues—especially in the U.S., Canada, and Australia—they’re always curious about how we monitor muscle and fat development in live animals. Two key traits come up every time: ribeye area (the size of the longissimus dorsi muscle) and backfat depth (the thickness of fat over the ribs). These are the things we scan using ultrasound—simple, non‑invasive, fast—and they say a lot about growth, yield, and even marbling.

Why ribeye area & backfat depth matter

When you scan between the 12th and 13th ribs, you get two measurements:

-

Ribeye area (REA): reflects muscling, expressed in square inches or cm²—bigger generally means better lean yield.

-

Backfat (rib fat) thickness: signals how much external fat has been deposited.

Together they feed into yield predictions (like USDA yield grade) and help forecast lean meat versus fat. That’s why extension agents from Mississippi State or University of Florida always highlight both traits when teaching ultrasound scanning.

Folks abroad often emphasize that ultrasound fat thickness correlates with actual carcass fat with very high accuracy—typically correlation coefficients from .75 to .96 in published studies. Ribeye area is less precise (correlations around .20 to .90), usually averaging around .73. But skilled techs still nail it within about 1 sq in of actual carcass area most of the time.

Getting those measurements right

Technicians trained by breed associations or certified under the Ultrasound Guidelines Council can collect data accepted for genetic evaluations or expected progeny differences (EPDs). Scanning is typically done on yearling bulls or heifers around 12–14 months of age—most breed groups specify windows like 320–440 days old.

On a practical note:

-

You position the probe perpendicular to the ribeye muscle (longissimus dorsi) and usually trace the ribeye area on the image.

-

Fat thickness is measured at about ¾ the length of the ribeye from the spine—this gives consistent measurement across animals.

How foreign beef producers interpret the data

Let me share what I hear from cattlemen in Kansas, Alberta, Uruguay, etc.:

-

They monitor REA relative to body weight, so you can tell not just how big the muscle is, but whether it’s big for that weight. In Canada, they often calculate WREA—REA per 100 lbs live weight.

-

In Uruguay’s Hereford steers, they did ultrasound scans every ~90 days from weaning to slaughter and modelled the growth of ribeye area over time, showing how it fits a Von Bertalanffy or Gompertz growth curve.

-

Everybody cares about backfat because it’s the main determinant of cutability. The sweet spot is around 0.3 in (≈ 7–8 mm). Too little fat risks chill toughening; too much lowers lean yield.

A snapshot of what a scan report might include

| Trait | Typical unit | Good range |

|---|---|---|

| Ribeye area (REA) | in² or cm² | 11–15 in² (≈ 70–100 cm²) |

| Backfat thickness | in or mm | 0.2–0.5 in (≈ 5–13 mm), ideal ≈0.3 in |

That’s the sort of table extension people in the U.S. would share.

Talking through a real case with a foreign colleague

“So, Bill, I just scanned a bull at 13 months. His REA came in at 14.8 in², and backfat was 0.28 in. He’s 1 100 lbs live. Sounds lean?”

Bill from Nebraska replies: “Yes, that bull looks muscular—REA is solid. With 0.28 fat, he’s at a healthy trim. Should grade Choice with good yield. If you leave him another month or feed energy, fat might creep up too much though.”

They often contrast larger ribeye area with lean finish as ideal for marketing: big REA boosts lean meat percentage; modest fat keeps USDA yield grade favorable.

Limits and things to watch for

Ultrasound isn’t perfect. Studies point out:

-

For fat thickness, errors are small—around 0.07 in bias on average. But ultrasound tends to overestimate on very lean cattle and underestimate on very fat ones.

-

For ribeye area, especially on small or heavy‑muscled cattle, ultrasound may overestimate or underestimate by 0.5–0.8 in².

-

Operator skill matters: inter‑operator variation affects accuracy, especially for ribeye area. Fat thickness tends to be more repeatable across techs.

Why I love using ultrasound in everyday ranch life

If I chat with producers in Australia or Brazil, everyone praises ultrasound for being fast, safe, and data‑rich. We can track growth at multiple timepoints—say at weaning, then mid‑test, then pre‑finish—and adjust diets based on whether animals are putting on more muscle or fat. That helps avoid over‑feeding or under‑finishing. It also helps sort uniform groups for slaughter or sale.

When muscle growth slows while fat builds up, that signals finishing time. For early‑maturing breeds like Angus, muscle peaks earlier. For later‑maturing breeds like Charolais or Limousin, muscle builds longer, and you might wait for fat to develop the right finish.

Also, genetic selection: bulls with high adjusted‑for‑weight ribeye area and moderate fat make better sires. Breed associations in North America use ultrasound data for EPDs—so you’re picking traits that pass down too.

Looking ahead

Internationally, more producers are combining ultrasound with 3D imaging or optical systems for more precise body composition data—even early work in Aberdeen Angus incorporates both. That could further refine marbling predictions and cut yield forecasts.

But for now, good quality real‑time ultrasound with a trained technician makes ribeye area and fat depth measurements robust tools for managing beef growth and deciding when to finish.

Wrap-up

Monitoring ribeye area and backfat depth via ultrasound gives you a snapshot of muscle and fat development in live cattle. These measurements help predict carcass yield, guide feeding decisions, and support genetic selection. Conversations with international peers confirm that accuracy depends on proper probe placement, skilled technicians, and data collected at consistent ages. When used well, ultrasound is a practical, proven way to enhance meat quality, efficiency, and margins.