Live Animal Evaluation: spotting growth in beef cattle and lamb

As a livestock farmer, I often chat with colleagues overseas—folks in Australia, Europe and the Americas—about how they judge growth in cattle and sheep before they ever hit a slaughterhouse. That’s where live animal evaluation comes in: it’s the art (and science) of seeing how an animal is shaping up before it’s too late to change course. Let’s zero in on how we do this in beef cattle and lamb, share what foreign producers think, and keep things down‑to‑earth in tone.

Why live evaluation matters

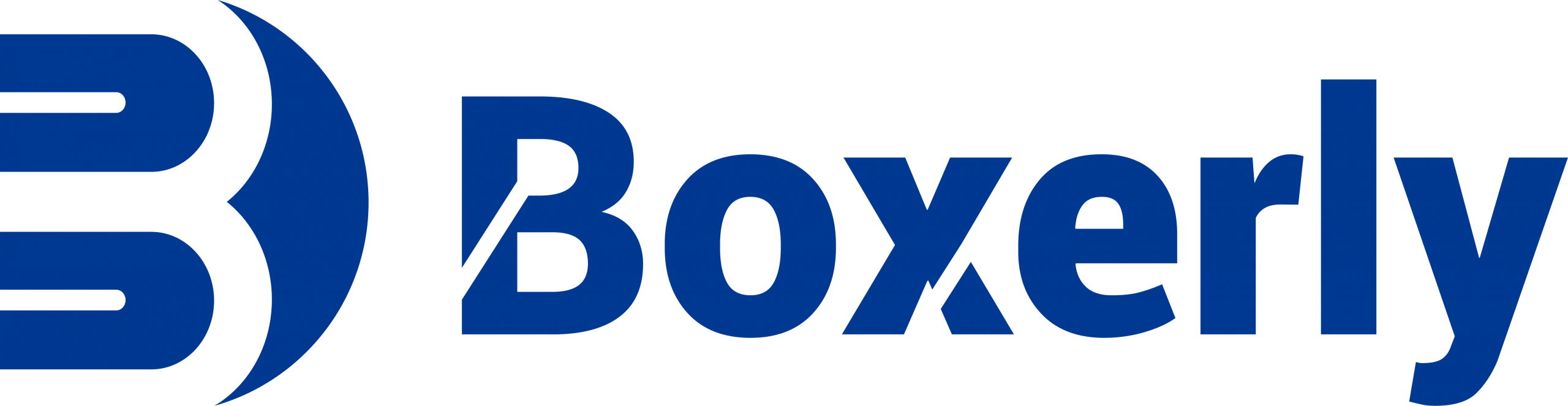

Most of us know that weighing an animal and eyeballing its condition tells you something—but the next level is rich with detail. Around the world, producers use real‑time ultrasound, sometimes combined with 3D imaging or optical sensors, to estimate meat quality and yield in living animals. That means you can see how much muscle is in the loin, how thick the backfat is, or even the likely marbling before slaughter. It’s non‑invasive, causes no stress, and happens while the animal is still in the pen. No surprises.

From ultrasound to on‑farm decisions

In the U.S., Europe and parts of Asia, producers scan yearling cattle between ribs 12 and 13, capturing longissimus dorsi images to estimate ribeye area, subcutaneous fat and marbling. For instance, breed associations mandate scanning windows—often around 365 days of age—to feed into national evaluation systems. Many European farms also train certified technicians following ICAR or Beef Improvement Federation guidelines, ensuring accurate, repeatable results.

Growth stage patterns: S‑curve in practice

When talking with European and Australian farmers, the consensus is the same: cattle grow in an S‑shaped curve. It starts slow as calves adapt, then leaps at puberty, then flattens as maturity approaches. The visible signs shift too: width and depth expand faster than height once the skeleton is done, and the eye muscle area grows rapidly until it’s time to shift focus to fat deposition. Ultrasound scans often reveal that muscle growth plateaus just before fat really kicks in. It’s the same story whether you’re in Nebraska or Devon.

How different countries apply evaluation

In Lithuania, for example, a study of 236 Angus bulls and 22 heifers found a strong link between live ultrasound parameters—fat thickness, loin area, marbling—and final carcass results. They even identified ideal weight thresholds for marbling to appear—roughly 430 kg for bulls, 600 kg for heifers. In New Zealand, researchers have tracked herds and shown that ultrasound traits combined with maternal data can improve breeding decisions and genetic selection.

Recently, experiments in North America integrated 3D imaging and optical sensors with ultrasound. They used these tools at feedlots to measure hip height and shape, refining predictions of carcass yield using live measurements.

What tools really tell you

Here’s a quick table to tie the common ultrasound metrics to decision points:

| Measure | What it means | How it helps |

|---|---|---|

| Ribeye area (Longissimus dorsi) | Muscle volume in loin region | Select for lean yield, choose finishing candidates |

| Backfat thickness (12‑13 rib) | Subcutaneous fat layer | Check readiness, avoid over‑fat animals |

| Rump fat depth | General fat deposition | Evaluate stage of fattening |

| Estimated marbling | Intramuscular fat | Predict meat quality grade |

Benefits seen around the world

Chatting with colleagues who’ve implemented this—from France to Argentina—I hear repeatedly: it’s fast, accurate, and affordable. A U.S. report even noted that using ultrasound can shrink progeny testing timelines from 4–7 years to just two years and reduce cost per sire from thousands of dollars to nearer 1 000 USD. It’s peaceful too—no need for slaughter, no animal stress. And live measurements feed back into genetic selection almost immediately.

Best practices: scanning prep and standards

To get reliable results, certain steps are universal. Animals need clipping at the scan site, clean skin using oil, a calm pen, and proper restraint in chutes—ideally in shade so weather doesn’t interfere. Ultrasound probes must be placed precisely between ribs, perpendicular to the muscle, with clear borders showing medial and lateral ends. Accuracy depends heavily on the technician’s skill—many breed groups maintain lists of certified scan operators.

Combining live evaluation with genetics and selection

Datasets from ultrasound traits feed directly into selection indices and Expected Progeny Differences in many countries. For example, U.S. seedstock breeding programs rely on ultrasound‑based phenotypes for carcass yield traits, which are moderately heritable. That means selecting for larger ribeye, thinner backfat or better marbling can shift the herd over time. European and Australian systems follow similar models—live scan data drives genetic progress in carcass quality.

Emerging tech: 3D and AI on the horizon

Looking ahead, breeders in North America and Europe are combining ultrasound with 3D imaging and AI‑based analysis to improve accuracy and automate the scan interpretation. Market research confirms that the animal ultrasound industry is growing at around 7 % CAGR, and demand for handheld, AI‑enabled scanners is rising fast in Asia and beyond. It’s becoming routine to ship images to cloud platforms, get instant trait predictions, and standardize evaluation systems across farms.

Final thoughts: how I talk about it with producers abroad

If I’m texting a friend in Ireland or New Zealand, I’ll say: “Just got ribeye area of 82 cm² on bull #34 at 365 days, backfat 6 mm, rump fat 7 mm—he’s exactly where I want for early finishing.” They’ll reply with what’s normal in their breed and their weights. It’s friendly, practical, grounded in field data. Evaluation like this lets you steer feeding plans, avoid over‑fattening, finish every animal to target, and tailor your breeding goals—all without guessing.