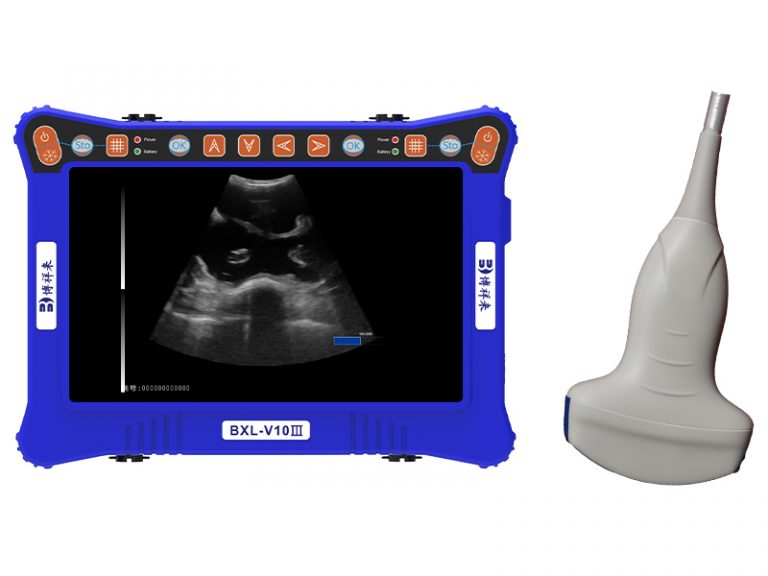

How to Maintain Veterinary Ultrasound Probes?

Veterinary ultrasound machines are essential tools for diagnosing and monitoring the health of animals, from pets to livestock. Among the most important components of these machines is the ultrasound probe. A well-maintained probe ensures accurate imaging, prolongs equipment life, and prevents cross-contamination between animals. Many veterinarians and technicians, however, underestimate the significance of routine probe maintenance. Let’s take a closer look at practical strategies, common pitfalls, and safety considerations for keeping veterinary ultrasound probes in top condition.

Why Probe Maintenance Matters

The ultrasound probe is the interface between the machine and the animal. Its surface comes into direct contact with the skin, fur, or mucous membranes, and sometimes even body fluids. Over time, debris, gel residue, and microscopic scratches can accumulate, which may reduce image quality and potentially transmit infections.

Neglecting probe maintenance can lead to blurry images, misdiagnosis, or even the need for costly replacements. For instance, a small scratch on the probe surface can scatter sound waves, reducing the clarity of internal structures. In a busy veterinary clinic, even minor image degradation can compromise decision-making, affecting both the health of the animal and the credibility of the clinic. Regular care is not just preventive; it directly impacts diagnostic accuracy.

Daily Cleaning Procedures

Proper daily cleaning is the first step in probe maintenance. After each use, the probe should be wiped with a soft, lint-free cloth to remove gel and debris. For areas in direct contact with mucous membranes, a mild, non-abrasive disinfectant is recommended. Alcohol-based wipes may damage certain probe materials, so it is crucial to follow the manufacturer’s guidelines.

Consistency is key. Many clinics use a simple checklist to ensure every probe is cleaned after every procedure. This routine prevents buildup that could harbor bacteria or fungi. Additionally, drying the probe completely before storing it avoids moisture-related damage. Daily cleaning is a small effort that pays off by extending the life of the probe and maintaining image reliability.

Disinfection and Sterilization

Beyond routine cleaning, probes occasionally require disinfection or sterilization, especially when used on multiple animals or invasive procedures. Not all disinfectants are suitable for all probe types. High-level disinfectants, such as glutaraldehyde or peracetic acid solutions, are effective against a wide range of pathogens but can be harsh on the probe’s surface if used improperly.

Some veterinary clinics adopt a tiered approach: low-level disinfectants for standard skin contact and high-level sterilization for probes entering body cavities. Temperature-sensitive or chemical-sensitive probes require specialized methods like UV sterilization or immersion in approved solutions. Documenting the disinfection process is also critical for regulatory compliance and quality control.

Handling and Storage Tips

Even the best cleaning routine is ineffective if probes are mishandled or stored incorrectly. Avoid dropping, bending, or twisting the probe cable, as this can damage internal wiring and affect signal transmission.

Proper storage includes keeping probes in padded holders or dedicated compartments to prevent accidental impacts. Environmental factors, such as high humidity or extreme temperatures, should also be controlled. Excessive heat can deform the probe head, while cold conditions may make the gel less effective during scanning. A storage checklist, similar to the cleaning routine, helps clinics maintain consistent care practices.

Common Maintenance Mistakes

Veterinary staff often make mistakes that shorten the lifespan of probes. One frequent error is using harsh chemicals without verifying compatibility, which can erode protective coatings. Another is skipping daily cleaning or disinfection steps due to time constraints.

Additionally, some users apply excessive gel during scans. While gel improves acoustic coupling, too much can seep into crevices, creating an environment for bacterial growth. Finally, not inspecting probes regularly for scratches, cracks, or cable wear can allow minor issues to escalate into major failures. Training staff on proper probe care and scheduling routine inspections can prevent these common problems.

Comparison of Maintenance Practices

The following table summarizes recommended practices for veterinary ultrasound probe care and highlights common mistakes to avoid:

| Maintenance Step | Recommended Practice | Common Mistakes |

|---|---|---|

| Daily Cleaning | Use soft cloth, mild disinfectant, remove gel completely | Skipping cleaning, using harsh chemicals |

| Disinfection | Follow manufacturer guidelines; tiered approach for low/high-risk uses | Using incompatible chemicals, over-immersion |

| Handling | Avoid dropping, bending, or twisting cables; gentle use | Rough handling, twisting cables sharply |

| Storage | Padded holders, controlled temperature/humidity | Leaving probes exposed or in extreme conditions |

| Inspection | Regular checks for scratches, cracks, or cable wear | Neglecting inspections, ignoring minor damage |

The Role of Staff Training

Maintaining ultrasound probes is not just a technical issue—it’s also about human habits. Veterinary clinics should invest in training programs for technicians and veterinarians. These programs cover proper cleaning techniques, correct handling, and how to spot early signs of damage.

Effective training ensures everyone in the clinic follows the same procedures, reducing variability and mistakes. It also empowers staff to act proactively, rather than waiting for problems to occur. Over time, a culture of consistent probe care improves both diagnostic quality and equipment longevity.

Conclusion

Veterinary ultrasound probes are crucial tools that require careful attention. Proper maintenance—including daily cleaning, disinfection, safe handling, correct storage, and staff training—directly impacts image quality, patient safety, and the life span of the equipment. Ignoring these practices can lead to inaccurate diagnoses, equipment damage, and higher replacement costs.

By adopting a structured maintenance routine and investing in staff training, veterinary clinics can ensure their ultrasound machines continue to perform at a high level. In turn, this supports better outcomes for animal patients and smoother operation for the clinic.